The development of robotic arms has revolutionized the manufacturing process, making use of precision, safety, efficiency, and other elements that were previously impossible. These marvels of the mechanical realm, commonly called robot arms, are essential in all industries and are driven by the imperative need to reduce operating costs while maintaining high standards of quality. Robotic arms are now integrated into production lines in order to reduce costs and improve safety. Find out how these machines have transformed the industrial landscape.

Image credit: automatedsolutions.com.au

The driving force behind the global surge in robotic arm usage is efficiency in cost. Owners of factories are under constant the pressure to decrease the risk of injuries at work, eliminate production errors, and cut down on waste. Robotic arms tackle these challenges head-on. Robot arms are more accurate than humans when it comes to performing repetitive tasks, cutting down on costs and avoiding costly errors. In high-volume industries like automotive manufacturing, robots ensure perfect assembly through precise welding and parts positioning. This precision translates to significant savings since fewer damaged products means less work and waste.

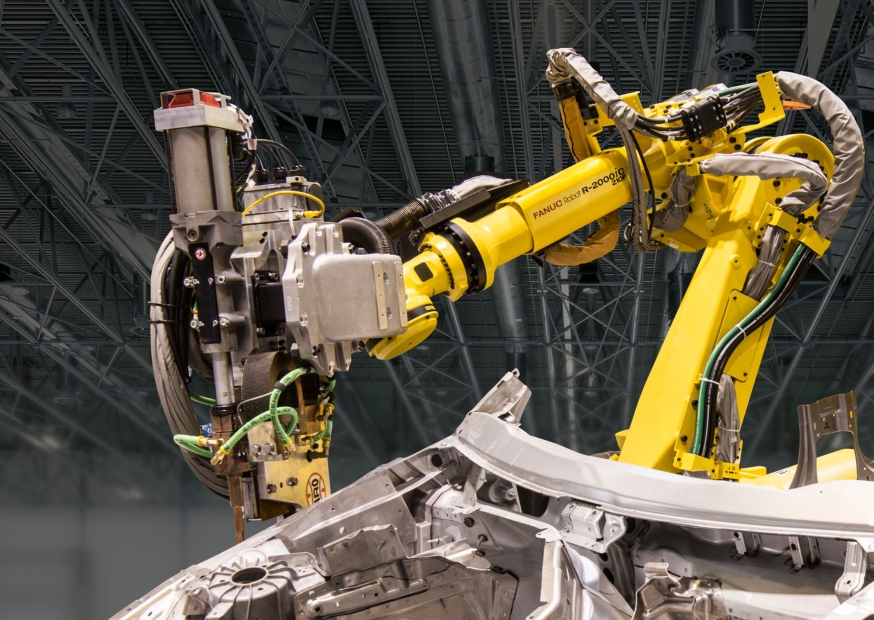

The security of robotic arms is an essential element. There are many manufacturing processes that require handling hazardous materials, or operating large machinery pose risks for humans. Robots allow businesses to remove their employees from dangerous environments and reduce workplace injuries. Robotic arms, which are built as a series of joints which move, are able to mimic the functions of human arms but without causing physical injury. With hand end effectors that allow these machines to do tasks that are dangerous for humans, such as spinning or welding.

The versatility of robotic arms makes them a game-changer across diverse industries. From assembly for automobiles to electronic production, robots can adapt to a broad range of jobs. The programming capabilities of these robotic arms allows them to execute complex tasks like painting or applying fiberglass with a high degree of precision. In the field of warehousing, robot arms have changed palletizing by making it easier to load goods onto pallets using precision and speed. Automation improves productivity and the reliability of robots as they work all the time, never tiring.

The growth of cobots (collaborative robots) that work with human workers is one of the most exciting innovations in the field. Cobots equipped with robotic arms unlike conventional industrial robots that are kept in isolated cells, are designed to interact with humans safely and effortlessly. Cobots that are equipped with robotic arms are able of performing the repetitive or heavy lifting task in a factory, which allows human workers to concentrate on more complex responsibilities. This collaboration enhances productivity and ensures a safe work space, since cobots are programmed to stop or alter their movements if a human is in the vicinity.

The impact of robotic arms extends beyond efficiency and safety into the very foundation of manufacturing today. Their capability to complete tasks such as welding and assembly or material handling with high accuracy has made them essential in high-stakes industries. For instance, in the manufacturing of automobiles, a robot arm can rotate and position parts during assembly, ensuring an exact alignment with no human intervention. Similarly, in electronics, robot arms handle delicate components with care, reducing damage and improving output quality.

Robotic arms are likely to grow in importance as industries grow. They are a cornerstone for the future of manufacturing due to their capacity to lower costs, enhance safety, and be able to adapt to different tasks. Combining cutting-edge technology and human creativity, robot arms are more than tools. They’re partners driving the pace of innovation and are changing how we design our environment.